SAVE WATER

SAVE FOREST

Sustainable Future For Greener World

“Now is the time to accelerate a transition to reduce ecological footprint of the textile industry.”

Increasing the Recycling of Textile Fibers is the Greener Choice.

One of the biggest negative environmental impacts comes from fabrics.

Textile production and -use have major impact on the environment

As a consequence, less cotton needs to be cultivated and the amounts of water, farmland, fertilizer and pesticides can be reduced on a large scale.

Keeping cotton in circulation for as long as possible contributes to a cleaner healthier world.

Textile Industry, One of the Major Causes of Water Pollution

The textile industry is one of the biggest industries in the world. Throughout the entire chain, from production and use to disposal, the textile industry has major consequences for people and the environment worldwide.

Large agricultural areas which are used to cultivate cotton are now, and in the future, necessary for cultivating food for a growing population. SaXcell can make a positive contribution to the solution of these major problems.

We build on the definition of the Ellen MacArthur Foundation, stating that a circular economy is the root cause of global tackle climate change, biodiversity loss and pollution by eliminating waste and pollution, keeping materials in use and restore natural systems.

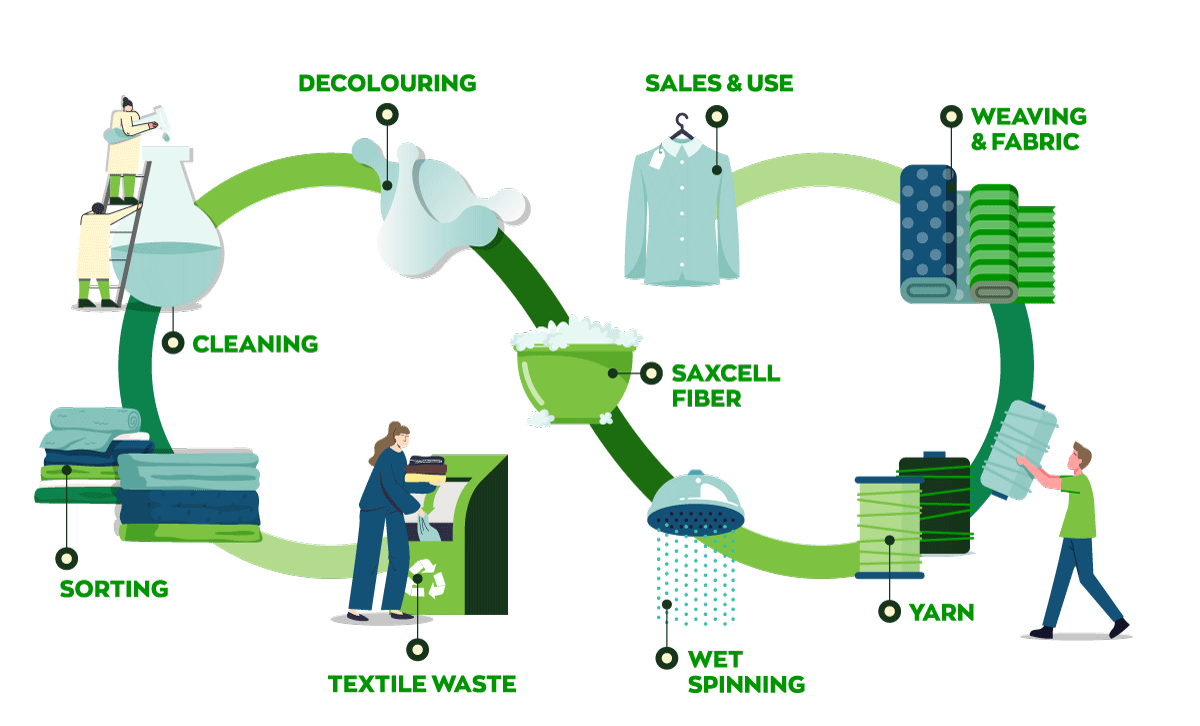

SAXCELL CIRCULAR ECONOMY

The SaXcell process offers for the first time

the possibility to make high end products out of cotton waste.

The reuse of clothing is of all times. The production of textiles from cotton has a large environmental impact.

Furthermore, the need for clothing is increasing and if no changes are made to the production chain, the e ects of the pollution will increase to the worse.

In addition to it, the pressure increases within the EU to reduce the imports of textiles from outside Europe.

SaXcell transforms waste cotton into a valuable raw material for new textile bres. New material from old materials: the circular economy in clothing.

Read more detailsRecycling to reduce waste

Reduce west to combat climate change

SAXCELL INNOVATIVE ASPECT

The unique aspect of the SaXcell technology is the processing of cotton waste into raw material, which can be used in standard downstream textile processes and leads to a high-end product. This type of recycling of cotton waste was, until now, not possible. The developed knowledge within the area of pulp properties and pulp production leads to the production of the innovative SaXcell ber with unique characteristics, namely:

- A higher tensile strength than cotton and regenerated fibers

- Very fine yarns can be spun

- A better depth of colour

- It can be processed on existing machinery

The SaXcell Process Offers for the First Time the Possibility to Make High End Products out of Cotton Waste.

Pure cotton towels are made using smart long twist technology for thicker and softer touch compared to usual cotton towels.

The result is a lofty towel with a soft, fluffy pile that has fascinating water absorbency and makes you feel heaven at your fingertips.

About SaXcell

SaXcell, an abbreviation of Saxion cellulose, is a regenerated virgin textile fiber made from chemically recycled domestic cotton waste. The process to transfer domestic cotton waste into SaXcell fiber is a crucial step in the circular textile chain.

Latest Posts

SaXcell CEO Erik van der Weerd and Board Members Visited Uğurlular Yarn Factory

Saxcell and Birla Cellulose sign memorandum of understanding for recycled fiber production to accelerate circularity.

CTD (Circular Textile Days) event held in Hertogenbosch, the Netherlands.

Clothing Companies Must Clean Up Their Own Waste Mountain.

New European initiative to support SMEs in transforming textile waste into value

The 11TH Workshop On Cellulose On Cellulose, Regenerated Cellulose And Cellulose Derivatives

Sustainability Talks Istanbul

Sustainability in the digitilised textile world towards 2030

Circular Textile Days

Get to know our new CEO Erik Van Der Weerd

Circular Economy

Our goal for the future is that eventually much more discarded textiles will be collected and processed into new products through our SaXcell process

Teaser opening pilot plant

Forcing clothing manufacturers to use recycled material

Consortium welcomes pilot cotton recycling plant

From workwear to workwear - SaXcell

New fabrics make recycling possible, but are they suitable for high street?

Saxcell re-uses cotton to produce yarn

SaXcell At Material District

Useful Links

Our Contacts

SaXcell BV Het Lentfert 38

7547 SR Enschede

(+90) 532 287 18 82