Regenerated ‘virgin’ cellulose fiber from cotton waste

SaXcell, an abbreviation of Saxion cellulose, is a regenerated virgin textile fibre made from chemical recycled domestic cotton waste. The process to transfer domestic cotton waste into SaXcell fibre is a crucial step in the circular textile chain.

SaXcell production starts with sorting domestic cotton textile waste into an as pure as possible, well-defined waste stream. The sorting can be done by hand as is customary now, or with the Identitex (a technique still in development).

Next, the pure waste stream is grinded and non-textile components like zippers, nails and buttons are removed. The result is a dry mixture of textile fibres with different fibre lengths. All fibre lengths, long and short, are suitable as raw material for SaXcell.

The dry mixture exists of different colours and is chemically decoloured and made suitable for the wet spinning process. Wet spinning can be done according Viscose or Lyocell processes. This means that the new fibre can be produced with few adjustments in the settings of machines on existing installations in Europe and Worldwide.

The end product of this step is SaXcell, a regenerated virgin cellulose fibre. The fibre can be cut to specified lengths, spun into yarns and woven or knitted into fabrics. Colouring can take place at the fibre, yarn or fabric.

SaXcell Fibers

Air-gap spinning: 1,7 dtex, fiber length: 38 mm

Strength: 43 cN/tex

stronger than cotton and other regenerated fibersElongation: 13%

Hydrophilic

Good dyeability

Dye efficiency: higher that expected

Cotton Recycling

Newsletter

Subscribe to our newsletter for the latest news, promotions and deals.

Popular Stories

About SaXcell

SaXcell, an abbreviation of Saxion cellulose, is a regenerated virgin textile fiber made from chemically recycled domestic cotton waste. The process to transfer domestic cotton waste into SaXcell fiber is a crucial step in the circular textile chain.

Latest Posts

Global Fibre Congress celebrated in Dornbirn

SaXcell CEO Erik van der Weerd and Board Members Visited Uğurlular Yarn Factory

Saxcell and Birla Cellulose sign memorandum of understanding for recycled fiber production to accelerate circularity.

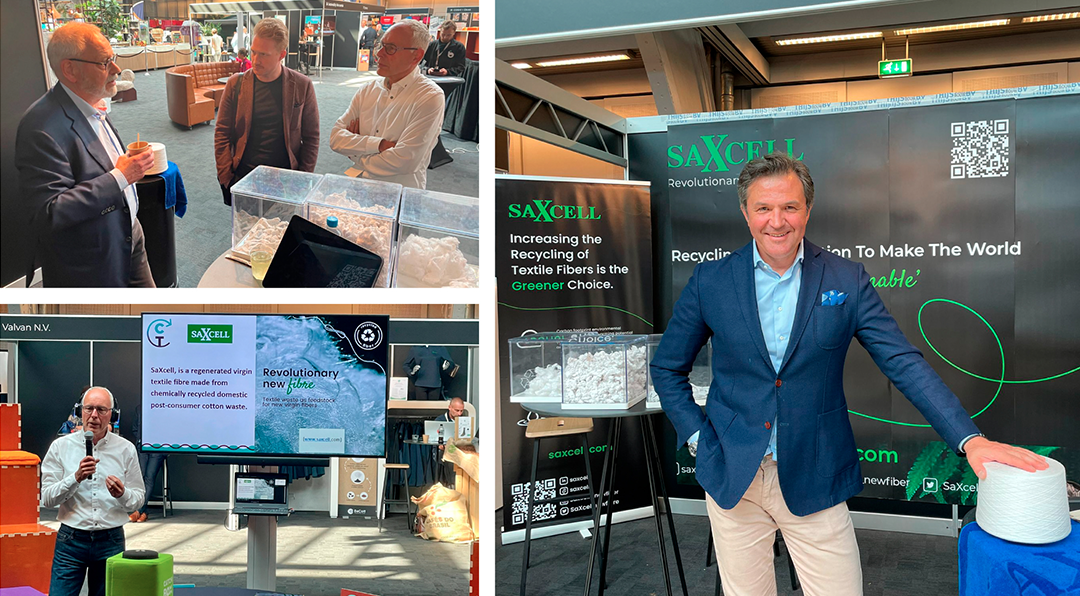

CTD (Circular Textile Days) event held in Hertogenbosch, the Netherlands.

Clothing Companies Must Clean Up Their Own Waste Mountain.

New European initiative to support SMEs in transforming textile waste into value

The 11TH Workshop On Cellulose On Cellulose, Regenerated Cellulose And Cellulose Derivatives

Sustainability Talks Istanbul

Sustainability in the digitilised textile world towards 2030

Circular Textile Days

Get to know our new CEO Erik Van Der Weerd

Circular Economy

Our goal for the future is that eventually much more discarded textiles will be collected and processed into new products through our SaXcell process

Teaser opening pilot plant

Forcing clothing manufacturers to use recycled material

Consortium welcomes pilot cotton recycling plant

From workwear to workwear - SaXcell

New fabrics make recycling possible, but are they suitable for high street?

Saxcell re-uses cotton to produce yarn

SaXcell At Material District

Useful Links

Our Contacts

SaXcell BV Het Lentfert 38

7547 SR Enschede

(+90) 532 287 18 82