Latest news

SaXcell ranks 6th in the Circular Economy category of the Dutch Chamber of Commerce (KvK) Innovation Top 100!

This recognition celebrates our commitment to driving innovation and sustainability in the textile industry.

The Digital Product Passport (DPP)

The Digital Product Passport (DPP) isn’t just about compliance—it’s a gateway to transparency, meeting consumer expectations, and paving the way toward a circular future.

Join us at the Sustainable Textiles Event 2024

Join us at the Sustainable Textiles Event 2024, hosted by Smithers, where our CEO, Erik van der Weerd, will present how SaXcell is transforming textile waste into high-quality cellulose fibers.

SaXcell Sustainable Process

Our process requires only 10 liters of water per kilogram of SaXcell fiber, compared to the 2,000 liters needed to grow one kilogram of cotton.

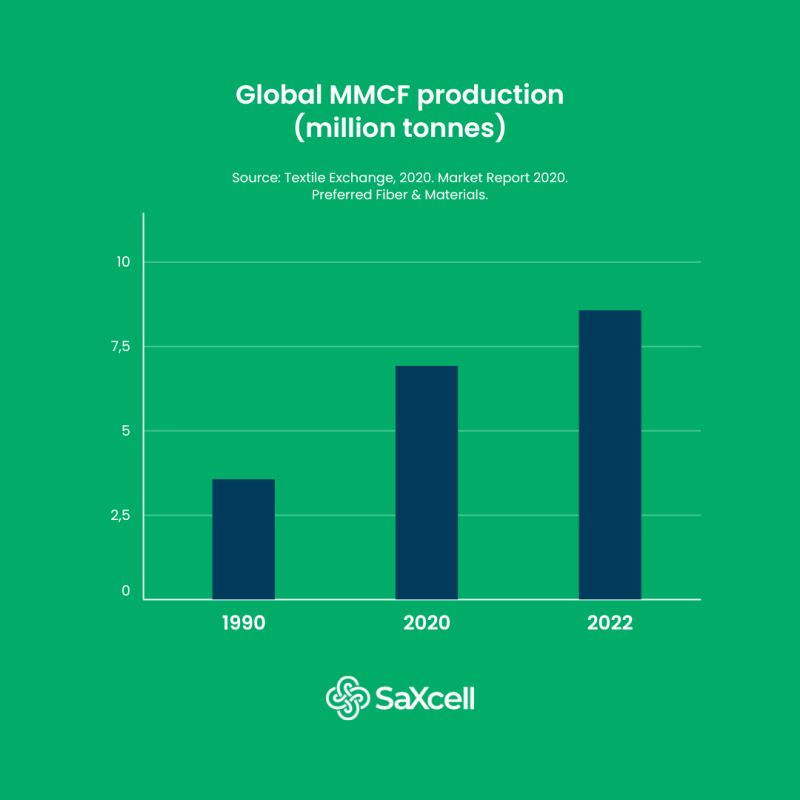

Man-Made Cellulosic Fibers (MMCF)

Man-Made Cellulosic Fibers (MMCF) are now the third most commonly used fiber globally, after polyester and cotton. With an annual production of about 7.1 million tonnes, MMCFs make up around 6.4% of the world’s fiber production.

At SaXcell, we’re dedicated to closed loop recycling

By transforming used textiles into high-quality recycled fibers, we create new raw materials that seamlessly integrate into existing supply chains—without the need for any changes to current production equipment.