Clothing Companies Must Clean Up Their Own Waste Mountain.

Importers and suppliers will be responsible for the waste generated by the

clothing they bring to the Dutch market as of July 1

At least half of that waste must be reused or recycled by 2025 This will

increase to 75% by 2030

New technologies, such as biodegradable yarn, are intended to help textile

companies comply with the legal obligation.

As of July 1, suppliers and importers will be responsible for the waste

generated by the clothing they bring to the Dutch market. Currently, 170

million kilograms of textiles still end up in waste heaps for incineration. New

technologies are intended to help with the herculean task of collecting,

reusing, or recycling more.

The company Wear2go from Valkenswaard has come up with smart sewing

thread. After seventy seconds in a large microwave, the stitches lose their

strength, says director John Beelen at the Circular Textile Days fair, which

took place this week in Den Bosch. Subsequently, the different materials of

used garments can easily be separated.

Beelen shows a container with zippers, RFID tags, and fluorescent stripes.

They are taken from orange safety vests of Rijkswaterstaat (the Dutch

Ministry of Infrastructure and Water Management). New jackets are made

from the stripped jackets. Wear2go sees recycling this workwear as a first

step. The Brabant-based company is ready to do this on an industrial scale

for recycling companies such as Suez or Veolia.

Responsible for cast-offs

Inventions like these can help companies comply with the Extended Producer

Responsibility for Textiles (UPV Textiles), which will take effect on July 1, says

Peter Koppert of the trade association Modint. Together with the retailumbrella organization Inretail, they have established the UPV Textiles

Foundation, which has nearly 350 companies as members.

C&A, Inditex, or H&M will no longer be solely responsible for the clothing they

trade but also for their customers' cast-offs. This is how the government

wants to encourage companies to reuse or recycle more waste. Other

sectors, such as tires, batteries, packaging, and electrical appliances, already

have such obligations.

The textile industry is one of the most polluting sectors, with significant water

pollution, greenhouse gas emissions, and waste disposal. Companies that

bring clothing, tableware, or bed linen to the Dutch market must report how

many kilograms they plan to trade from this summer onwards. Subsequently,

they must establish and finance a collection and processing system. Koppert

expects the levy to be a few cents per garment.

At least half of the waste must be reused or recycled by 2025 This will

increase to 75% by 2030 The current percentage is 35%, but it is not high-

quality. "I think only 2% is truly reused, through thrift stores," says Koppert.

He estimates the share of high-quality fiber-to-fiber recycling to be a

maximum of 1%.

Bra with deposit

So, there's work to be done. "The law is a stick behind the door," says Terry

Hommelberg, sustainability manager at lingerie chain Livera. "Sustainability

used to be at the bottom of the priority list, but now it's at the top." She

assembled a Green Team of ten people, which is significant for Livera's small

headquarters. Last week, they started a pilot collection system in six of their

own stores.

Hommelberg expects that it will take some time before there are fabrics that

can be reused for lingerie. "We're still quite far from that moment. Our

suppliers in China and India look at us very strangely when we say we want

to reuse clothing. But I'm glad that our French parent company, Groupe

Chantelle, has developed a 100% recyclable bra with a deposit."

Geert Doorlag, a researcher at bed manufacturer Auping, also believes that

the law will help involve colleagues in sustainability efforts. He already has

experience with a UPV (Extended Producer Responsibility) for mattresses

from last year, which aims to collect 75% of mattresses by 2028 "I must say,

I felt more positive about mattresses than about UPV Textile. But now that

I'm walking around this fair, I'm becoming more positive."

Chemical recycling factory

In Den Bosch, there are companies with technologies for textile recycling.

Circularity from Etten-Leur cuts used workwear and clothing surplus into

pieces and turns them into new yarns. The company then uses those yarns to

make new t-shirts and sweaters without the need for new raw materials.

"Companies like H&M, Zeeman, and C&A have already approached us," says

Micha Vugts from Circularity.

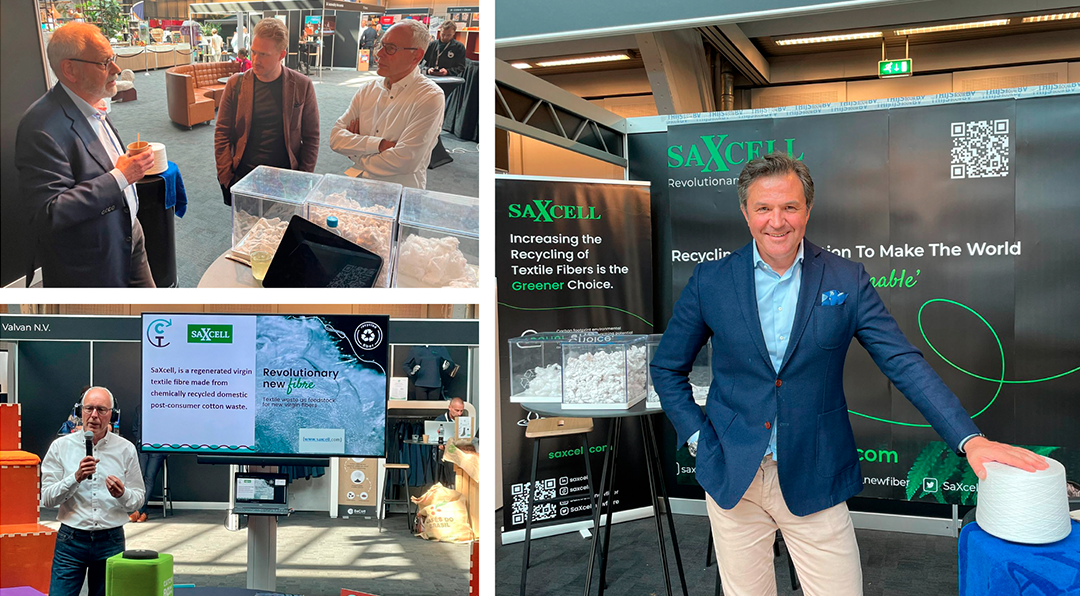

Erik van der Weerd, director of Saxcell, also sees more interest. He points to

strips of terry cloth. "These are towels that have been used in a hotel. We

turn them into pulp, and from that pulp, we make new fibers. The same fibers

as those made from wood. This way, we solve two problems: textile waste

and forest protection."

The company plans to open a small factory in Enschede that can process

three million kilograms of textiles. Saxcell currently mainly works with hotels,

but the first streams of consumer textiles are emerging. "In the startup

phase, we still need the help of clothing companies," says Van der Weerd.

"Recycled material is still more expensive than new raw materials."

There are also challenges in clothing collection. "We see the quality of

collected clothing deteriorating further," says Mert Ozturk from Erdotex, a

company in Ridderkerk that sorts two hundred tons of clothing daily at

various locations. "There are more and more items from Primark that are

completely worn out. That puts pressure on our business case."

Ozturk hopes to receive a portion of the financial compensation that

companies will pay for collecting and recycling clothing. He notes that the

new law is already casting its shadow. "We're being approached from two

sides: by clothing brands and retailers, and by recycling companies looking

for collected clothing."